Assembly Automation

Process Analysis and Design:

The first step in automating assembly is analyzing the existing manual assembly processes. Engineers assess tasks, identify bottlenecks, and determine which operations can be automated for maximum efficiency. Process design may involve choosing the right technologies and determining how to integrate them into the existing workflow.

Selecting Automation Technologies:

Various technologies are used to automate assembly operations, including:

1. Robots (Industrial Robots & Cobots): Robots perform tasks such as picking, placing, fastening, and packaging with high speed and precision.

2. Conveyor Systems: Automated conveyors transport components between different stages of the assembly process, reducing manual handling and improving flow.

3. Vision Systems: Vision systems with cameras and sensors enable robots to inspect, guide, and verify assembly operations.

4. Machine Learning and Al: These technologies help robots adapt to new tasks, optimize processes, and predict maintenance needs based on data analysis.

The Challenges You Face

When it comes to system integration, many companies struggle with:

- Finding specialized expertise that understands your unique requirements.

- Meeting stringent quality standards while controlling costs.

- Coordinating complex technical requirements across multiple disciplines.

- Scaling production capabilities without sacrificing quality.

The Real Cost of Poor System Integration

Without expert system integration, your projects face:

- Significant delays in product development.

- Expensive rework and quality issues.

- Competitive disadvantage in fast-moving markets.

- Higher overall project costs and extended timelines.

The Utech Manufacturing System Integration Advantage

Our specialized approach delivers exceptional results for your most challenging system integration needsSeamless communication between system components

Our system integration expertise ensures that you receive the highest quality results, every time.

Optimized workflow and productivity

Our system integration expertise ensures that you receive the highest quality results, every time.

Reduced downtime through intelligent design

Our system integration expertise ensures that you receive the highest quality results, every time.

Our System Integration Process

A proven approach tailored specifically for your system integration needsRequirements Analysis

We begin with a thorough analysis of your system integration requirements, ensuring we understand all specifications.

Solution Design

Our experts design a customized system integration solution that addresses your specific challenges.

Implementation

We implement the solution with precision, following established best practices and quality controls.

Quality Verification

Rigorous testing and verification ensure that the final deliverable meets all specifications and quality standards.

Applications for System Integration

Our system integration services are utilized across various industries and applicationsFactory automation systems

Our system integration expertise delivers exceptional results for custom production cells applications, ensuring optimal performance and reliability.

Custom production cells

Our system integration expertise delivers exceptional results for custom production cells applications, ensuring optimal performance and reliability.

Legacy equipment modernization

Our system integration expertise delivers exceptional results for legacy equipment modernization applications, ensuring optimal performance and reliability.

Data collection and analysis systems

Our system integration expertise delivers exceptional results for data collection and analysis systems applications, ensuring optimal performance and reliability.

Related Services

Precision Manufacturing

High-tolerance parts with consistent quality

Custom Machine Design

Specialized equipment built

CNC Machining

Multi-axis machining for complex geometries

PRECISION MACHINING

U Tech Manufacturing is a precision machine shop for parts fabrication using in-house 4 and 5 axis CNC mill and lathe machines, sheet metal, welded and extruded equipment frames.

EQUIPMENT DESIGN AND BUILD

U Tech Manufacturing’s vertically integrated process allows us to shorten design to prototype to production cycle times of simple to complex equipment builds in our local facilities in California.

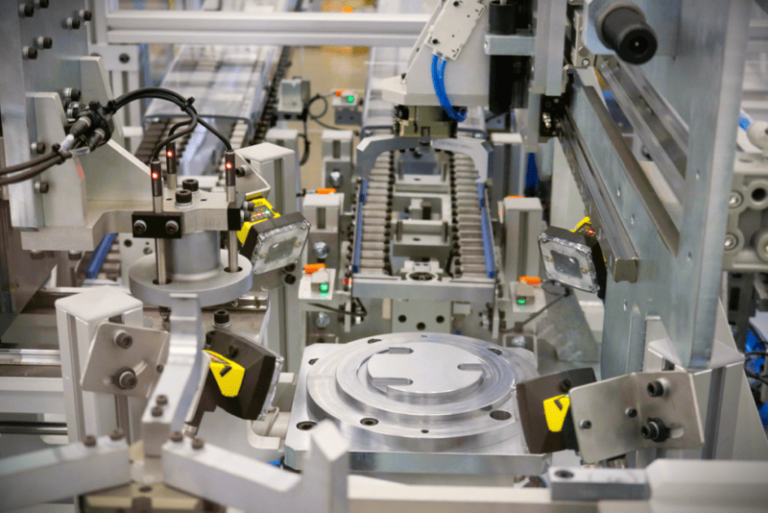

ASSEMBLY AUTOMATION

U Tech Manufacturing specializes in automation of manufacturing assembly processes using standard equipment to fully customized automation equipment for complex applications.

The Resource-Optimized Development Guide

5 Strategies for Accelerating Technical Innovation with Limited Teams

- Learn how to prioritize technical development efficiently.

- Discover outsourcing strategies that actually work.

- Case studies from semiconductor and energy companies.